|

Extrusion-based 3D Bioplotter • Make: EnvisionTec • A liquid, melt, paste or gel is dispensed from a material cartridge

through a needle tip from a 3-axis system to create a 3D object • Individual temperature control of each printing head, both in the

parking positions, as well as during printing • Designed for use in a sterile environment within a biosafety cabinet. |

|

Biomedical Printer |

|

Extrusion-based 3D Bioprinter • Make: RegeMat • Nozzle diameter: 0.1 - 0.5mm • Build volume: 150mm x 150mm x 110m • Vertical resoultion: 400nm • Printing platform: Crystal or petri dishes |

|

Biomedical Printer |

|

3D bio-Printer • Model/Make: Biobots • 3D bio-printer based on Extrusion based technology • In addition it has blue light based crosslinking capability for bio

hydrogels • Layer Thickness: 0.2mm • Model material: Hydrogels like alginate, gelatin, collagen, hyaluronic

acid. |

|

Biomedical Printer |

|

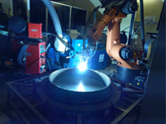

Wire-Arc Additive Manufacturing (WAAM) • Wire-Arc Additive Manufacturing setup for large sized components • Setup developed at IITH by retrofitting a Cold Metal Transfer (CMT)

GMAW system with a CNC machine • Components upto size 600mm x 400mm x 400mm possible. • Minimum features upto 4mm possible. • Materials: All weldable materials • CNC Model: AGNI BMV 45, BFW (along with trunnion table setup) • Weld-Deposition: CMT, Fronius |

|

Metal 3D Printer |

|

Twin-Wire WAAM • Twin-wire based WAAM setup for functionally gradient components. • Setup developed at IITH by integrating a twin-wire welding system with

a Kuka robot. • Components upto size 1200mm x 1200mm x 600mm possible. • Minimum features upto 6mm possible. • Materials: All weldable materials • Robot Model: KR 30-3 Robot, Kuka • Weld-Deposition: TimeTwin Digital, Fronius |

|

Metal 3D Printer |

|

Powder Bed Fusion • Model/Make: GE, Mlab 200R • Laser Power: Fibre laser 200 W (cw) • Build volume: 100 x 100 x 100 mm • Layer thickness: 15-30 microns • Scanning speed: max 7 m/s • Materials: aluminum alloys, tool steels, inconel alloys, titanium

alloys • Machine yet to be installed;

expected to be ready by Mar 2020. |

|

Metal 3D Printer |

|

Direct Energy Deposition (DED) • Laser + Powder based Direct Energy Deposition system. • Laser: 2kW fiber laser, Coherent • Cladding: YC 52 Precitec Cladding head • Kinematic setup capable of 5-axis deposition |

|

Metal 3D Printer |

|

Composite (Carbon Fiber & Fiberglass) 3D Printer • Specifications of a MarkTwo printer are: • Build Volume 320 mm x 132 mm x 154 mm • Plastic Materials Onyx • Fiber Materials, Carbon Fiber, Fiberglass,

Kevlar, HSHT (High Strength High Temperature) Fiberglass • Z Layer Resolution: 100 micron |

|

Composite 3D Printer |

|

Multi-Colour Binder Jetting 3D Printer • HP Jet Fusion 580 Color 3D Printer. • Binder Jetting technology based 3D printing

capable of Multi-Colour components • Minimum Build Volume: 300mm x 150mm x 200mm • Layer thickness: 0.1mm • Resolution: 1200dpi • This machine is

available in the i-TIC facility on the IITH premises. |

|

Polymer 3D Printer |

|

Stereolithography (SLA) • ProJet6000, 3D Systems, USA. • Stereolithography (SLA) based 3D printing technology • Capable of printing transparent designs at 6 micro resolution and 0.2%

accuracy • Resin material is bio-compatible (non-toxic and autoclave-able) • In the purchase procedures; expected to be available in IITH in near

future. |

|

Polymer 3D Printer |

|

FDM based 3D Printer: Nylon material • Make: Stratasys • Model: Fortus 450 MC • Build Volume: 406 x 355 x 406 mm • Accuracy: ± 0.127 mm • Materials: ABS ESD7, ABS M30, Antero800NA, FDM Nylon 12, PC-ABS, PC

-ISO, ULTEM 9085, ULTEM 1010, ST 130. |

|

Polymer 3D Printer |

|

FDM based 3D Printer: ABS material • Model/Make: uPrint SE, Stratasys • 3D printer based on Fused deposition modelling technology • Capable of creating complex shapes from a CAD file • Maximum Build Size: 203 mm x 152 mm x 152mm • Layer Thickness: 0.254mm • Model material: ABS plastic |

|

Polymer 3D Printer |

|

FDM based 3D Printer: OpenSource based • Alfatek printer • Fused deposition modeling based 3D printer • Capable of printing ABS , PLA and other polymers • Capable of printing at micrometer range ( 750 -800 micron with 2%

accuracy) |

|

Polymer 3D Printer |

|

Vat Polymerization based 3D Printer • Make: Formlab • Capable of printing various biocompatible resins including transparent resin • Devices can be printed with approximately ( 300 micron with 2 % accuracy) |

|

Polymer 3D Printer |

|

3D Reverse Engineering System • Model/Make: FaroArm Fusion • CMM Type: 7-axis portable arm type • Measuring Range: 1.8 meters • Scan Method: Both contact (probe) and non-contact (Laser) • Laser Scanner Rate: 19,200 points per second • Softwares: CAM 2 Measure 10, Geomagic Studio 2012 |

|

Characterization |

|

Transmission Electron Microscope • JEOL 2100FX, operating voltage 200 kV, LaB6 filament • Microstructural characterization at nanometer scale • STEM mode for high resolution scans and maps • EDS for composition analysis and mapping |

|

Characterization |

|

Scanning Electron Microscope • JEOL 7800F FE-SEM • Nanometer level resolution • EDS, WDS and EBSD detectors for composition and crystal orientation

analysis and mapping |

|

Characterization |

|

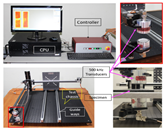

Immersion ultrasonic system: • Immersion scanning system supplied Blue Star Engg. • Tank size- 1000 mm x 600 mm x 400 mm • Scanning axes- X, Y, Z and R • Scanning speed 50mm/sec • Motion control software • Immersion probes 2.25 MHz, 5 MHz, 7.5 MHz. • Material characteristics: Delamination, porosity, Thickness, cracks. |

|

Characterization |

|

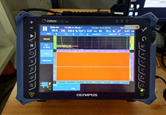

Phased array ultrasonic system: • Olympus MX2 Phased array system. • Electronic beam steering, Dynamic depth focussing • Phased array probes 2.25 MHz, 3.5 MHz, 5 MHz • Curved phased array probes • A, B , C and sectorial scans • Composite and sandwich structure inspection • Weld inspection |

|

Characterization |

|

Non-contact ultrasonic system: • Ultran air coupled ultrasonic system • Pulser voltage: 400 V • Frequency range: 20 KHz to 6 MHz • Scanning area: 600 mm x 600 mm • Scanning speed: up to 1 m/s • Sampling rate: up yo 50 MS/sec • Material characteristics: Delamination, porosity, Thickness, cracks |

|

Characterization |

|

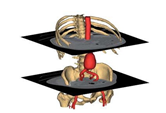

Mimics (software for Medical AM) • Mimics is an acronym for Materialise Interactive Medical Image Control

System • Used to create 3D surface models from stacks of 2D image data (CT/MRI

Scan data) • These 3D models can then be used for a variety of studies including

FEA analysis, implant design etc. |

|

Software |

|

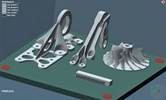

Simufact Additive • Meant for simulation of the additive manufacturing process • Simufact Additive covers the simulation of • Powder Bed Fusion processes, • Electron Beam Melting (EBM) • Directed Energy Deposition (DED) |

|

Software |